by

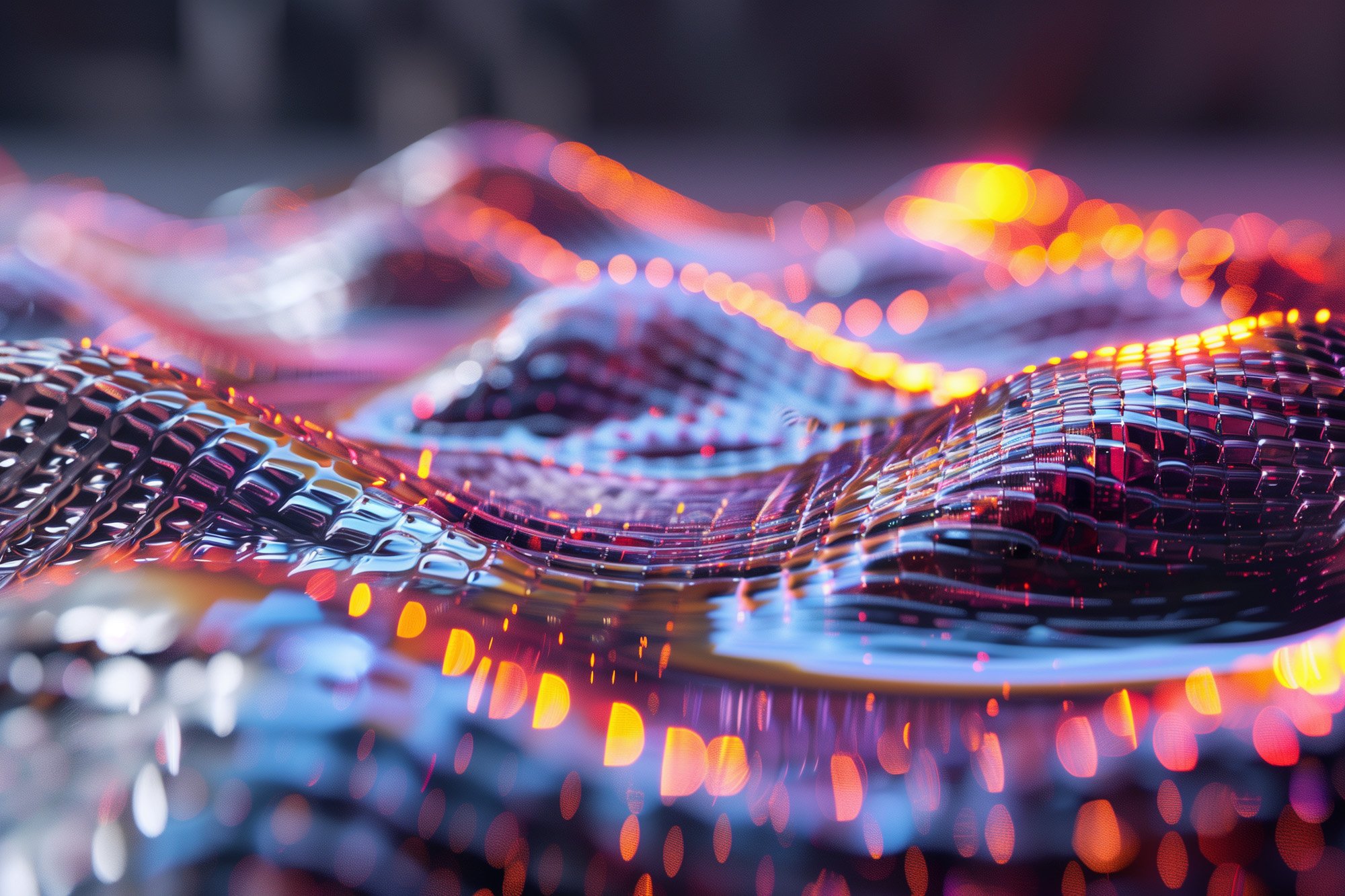

Harvard researchers have created a versatile, programmable epitaxial fluid that can change its properties, including viscosity and optical transparency, in response to pressure. This new class of fluids has potential applications in robotics, optical devices, and energy dissipation, offering a major breakthrough in metamaterial technology. (Artist's concept). Credit: SciTechDaily.com

Scientists have developed a meta-fluid with a programmable response.

Scientists at John A. Harvard's Paulson School of Engineering and Applied Sciences (SEAS) has developed a programmable metafluidic fluid with tunable elasticity, optical properties, viscosity, and even the ability to transition between Newtonian and non-Newtonian fluids.

The first-of-its-kind metafluorescent liquid uses a suspension of tiny rubber balls – between 50 and 500 microns – that flex under pressure, radically changing the properties of the liquid. Metafluidic can be used in everything from hydraulic actuators to programmable robots, to smart shock absorbers that can dissipate energy depending on the severity of the impact, to optical devices that can go from clear to opaque.

The research is published in nature.

“We are only scratching the surface of what is possible with this new class of fluids,” said Adel Jalouli, a research associate in materials science and mechanical engineering at SEAS and first author on the paper. “With this one platform, you can do a lot of different things in a lot of different areas.”

Metafluids vs Solids

Metamaterials – engineered materials whose properties are determined by their structure rather than composition – have been widely used in a range of applications for years. But most materials — such as pioneering metallic minerals in the laboratory of Federico Capasso and Robert L. Wallace, a senior research fellow in electrical engineering in the Fenton Hayes School of Applied Sciences – are solids.

Adjustable optics with the Harvard University logo displayed below the metafluorescent fluid. Credit: Harvard University SEAS

“Unlike solid metamaterials“Metaphoric fluids have a unique ability to flow and adapt to the shape of their container,” said Katia Bertoldi, the William and Amy Cowan Danoff Professor of Applied Mechanics in the College of Applied Sciences and senior author of the paper. “Our goal was to create a meta-fluid that not only had these great attributes, but also provided a platform for programmable viscosity, compressibility, and optical properties.”

Using a highly scalable manufacturing technology developed in the laboratory of David A. Weitz, the Mallinckrodt Professor of Physics and Applied Physics at SEAS, the research team produced hundreds of thousands of these highly deformable, air-filled spherical capsules and suspended them in silicone oil. . When the pressure inside the fluid increases, the capsules collapse to form a lens-like hemisphere. When this pressure is removed, the capsules return to their spherical shape.

Metafluid Properties and Applications

This transformation changes several properties of the fluid, including viscosity and opacity. These properties can be adjusted by changing the number, thickness and volume of capsules in the liquid.

The researchers demonstrated the programmability of the fluid by loading the metaphysical fluid into a hydraulic robotic gripper and having the gripper pick up a bottle, an egg, and a berry. In a simple traditional air- or water-powered hydraulic system, the robot would need some sort of external sensor or control to be able to adjust its grip and pick up the three objects without crushing them.

But with metafluid, there is no need for sensing. The fluid itself responds to different pressures, changing its conformity to adjust the force of the handle so it can pick up a heavy bottle, a delicate egg, and a small berry, without additional programming.

“We showed that we can use this fluid to give intelligence to a simple robot,” Jalouli said.

The team also demonstrated a fluidic logic gate that can be reprogrammed by changing the metafluidics.

Optical properties and states of liquids

Metafluid also changes its optical properties when exposed to varying pressures.

When the capsules are round, they scatter light, making the liquid opaque, just as air bubbles make carbonated water appear white. But when pressure is applied and the capsules collapse, they act like tiny lenses, focusing light and making the liquid transparent. These optical properties can be used for a range of applications, such as electronic inks that change color based on pressure.

The researchers also showed that when the capsules are spherical, the metafluid behaves like a Newtonian fluid, meaning its viscosity only changes in response to temperature. However, when the capsules collapse, the suspension turns into a non-Newtonian fluid, meaning its viscosity will change in response to the shear force – the greater the shear force, the more fluid it becomes. This is the first meta-fluid that has been shown to transition between Newtonian and non-Newtonian states.

Next, the researchers aim to explore the acoustic and thermodynamic properties of superfluids.

“The application space for these scalable, easy-to-produce metafluids is huge,” Bertoldi said.

Reference: “Shell Indentation for Programmable Metafluids” by Adel Jalouli, Bert van Raemdonck, Yang Wang, Yi Yang, Anthony Caillaud, David Weitz, Shmuel Rubinstein, Benjamin Goersen, and Katja Bertoldi, April 3, 2024, nature.

doi: 10.1038/s41586-024-07163-z

Harvard University's Office of Technology Development has protected the intellectual property associated with this research and is exploring commercialization opportunities.

This research was supported in part by NSF through Harvard University Materials Research Science and Engineering Center Grant No. DMR-2011754.

“Hipster-friendly explorer. Award-winning coffee fanatic. Analyst. Problem solver. Troublemaker.”

/cdn.vox-cdn.com/uploads/chorus_asset/file/25550621/voultar_snes2.jpg)

More Stories

This $60 Chip Fixes a Long-Standing Super Nintendo Glitch

Google’s New Nest Thermostat Features Improved UI and ‘Borderless’ Display

New York Times Short Crossword Puzzle Hints and Answers for Monday, July 29